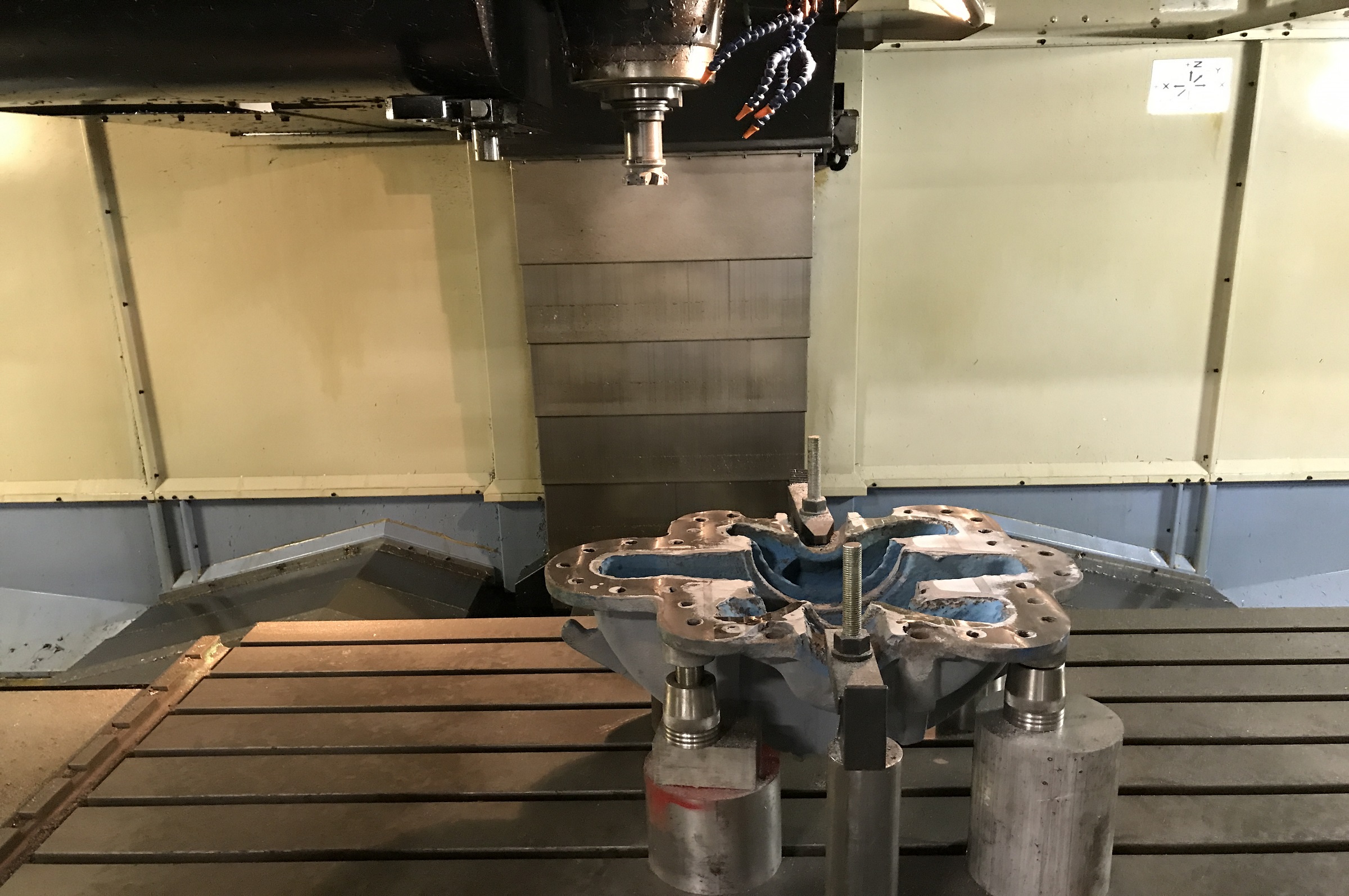

Frontline Industries specializes in overhauling all types of Centrifugal and Positive Displacement Pumps for the largest Industrial Facilities of the Northeast. With over 38 years of experience, state of the art equipment, and a highly skilled team, Frontline Industries is uniquely positioned to help its customers reduce downtime, extend equipment life, optimize performance and lower maintenance costs.